1. The processing center safety procedures must be observed.

2. Before work, wear protective equipment and tie the cuffs. Do not wear scarves, gloves, ties, or aprons. Women workers should be in the hat.

3. Check whether the tool compensation, machine zero, workpiece zero, etc. are correct before starting.

4. The relative position of each button should meet the operational requirements. Carefully prepare and input the NC program.

5. Check the operation status of hungry protection, insurance, signal, position, mechanical transmission part, electrical and hydraulic digital display on the equipment, and cut it under all normal conditions.

6. CNC pre-machining machine test run, should check the lubrication, mechanical, electrical, hydraulic, digital display and other systems operating conditions, under all normal conditions can be cut.

7. After the machine tool enters the machining operation according to the program, the operator is not allowed to contact the workpiece, the cutter and the transmission part of the athlete. It is forbidden to transfer or take tools and other items through the transmission part of the machine tool.

8 When adjusting the machine, clamping the workpiece and tool, and wiping the machine, it must be stopped.

9. Tools or other items must not be placed on appliances, operating cabinets and protective covers.

10. Do not remove the iron filings directly by hand. Use special tools to clean.

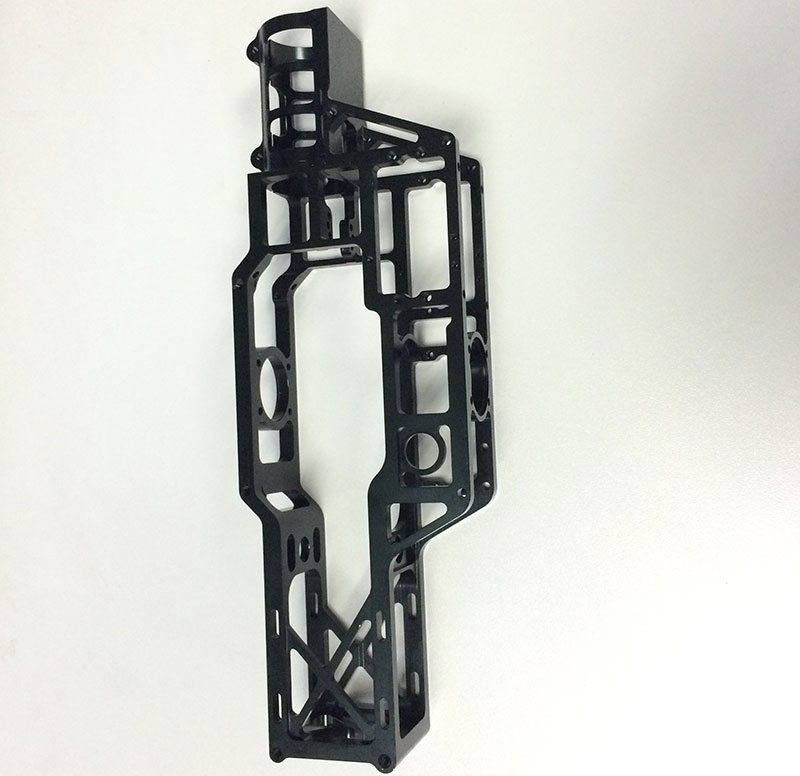

Jingzhixing is specialized in produce CNC Processing Brass Parts. Our products are very popular, if you are interested in our products, please contact China Machine Parts Factory as soon as possible.