Features of CNC machining Aluminum parts:

Lathe machining is part of machining. There are two main types of machining: one is to fix the turning tool and to process the unformed workpiece in the rotation; the other is to fix the workpiece through the high-speed rotation of the workpiece, the turning tool ( The lateral and longitudinal movement of the tool holder) is precision machined.

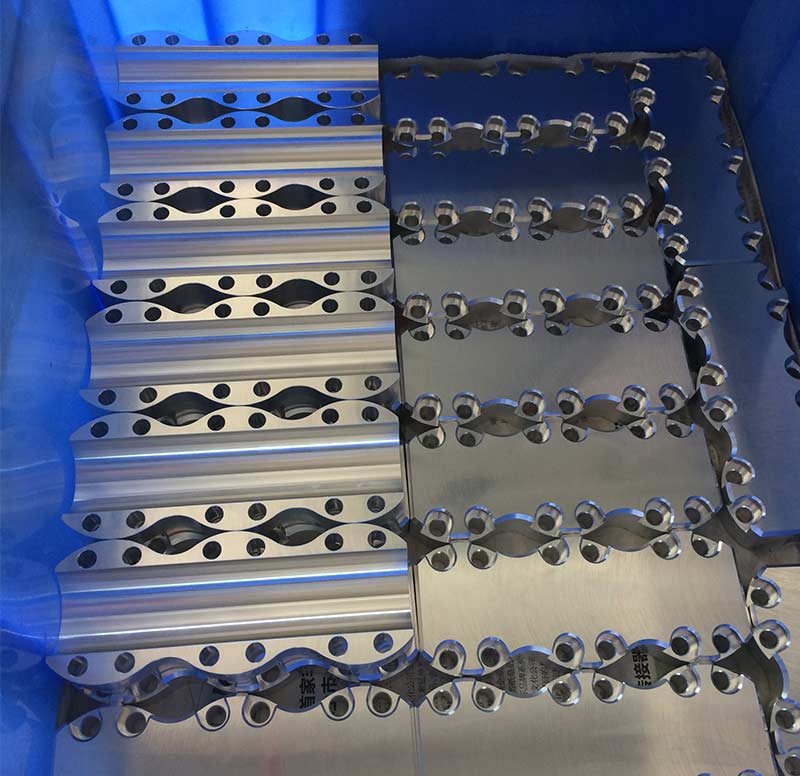

CNC lathe machining usually consists of control system, servo system, inspection system, mechanical transmission system and other auxiliary systems. On the lathe, drills, reamer, reamer, tap, die and knurling tools can also be used for corresponding processing. CNC lathe processing recognizes Titanium, which is mainly used for machining shafts, discs, sleeves and other workpieces with a rotating surface. It is the most widely used type of machine tool in machinery manufacturing and repairing plants. CNC custom aluminum parts is an important CNC lathe machining.

The materials commonly used in modern lathe processing use aluminum alloy materials. The density of aluminum alloy materials is greatly reduced compared with the density of iron and steel materials, and the lathe processing is difficult, the plasticity is strong, the weight of the product is greatly reduced, and the lathe machining parts are greatly shortened. The time comes with the cost reduction that makes aluminum alloy the darling of the aerospace sector.

CNC lathe processing technology:

1. It is easy to ensure the precision of each processing surface of the workpiece; when machining, the workpiece rotates around a fixed axis, and each surface has the same rotation axis, so it is easy to ensure the coaxiality between the processing surfaces.

2. The cutting process is relatively stable; in addition to the discontinuous surface, in general, the lathe processing process is continuous, unlike milling and planing, in the process of a pass, the cutter has multiple cuts and cuts, resulting in Shock.

3. It is suitable for the finishing of non-ferrous metal parts; some non-ferrous metal parts have good hardness due to the low hardness of the material itself, and it is difficult to obtain a smooth surface by other processing methods.

4. The tool is simple; the turning tool is the simplest one of the tools, manufacturing, sharpening and installation are very convenient, which is convenient to select a reasonable angle according to the specific processing requirements.