How to process precision parts to maintain high strength:

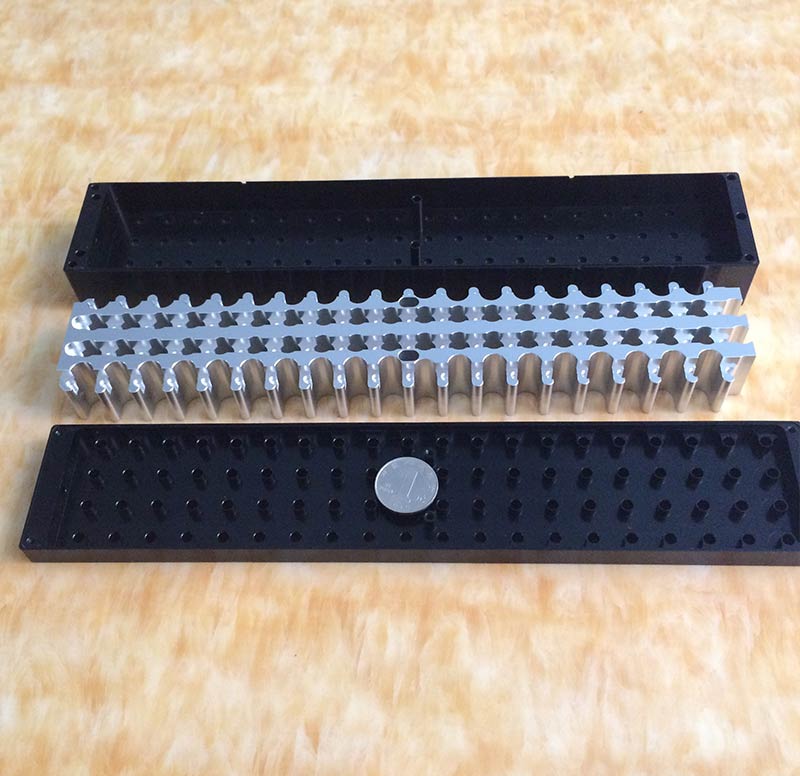

It is important to ensure high strength of parts, such as CNC Machining Aviation Model Accessories.

The principles and measures to improve the strength of parts are: using high-strength materials, heat treatment to improve the strength, reduce the internal stress, control the processing process, reduce or eliminate micro-defects, and strive to reduce the load of parts. In order to increase the rotary inertia of the section, the size of the dangerous section of the parts is enlarged, and the shape of the section is designed reasonably, so as to increase the rotary inertia of the section.

CNC precision parts processing can be multi-coordinate linkage, can process complex shape parts, high precision,such as precision Hardware Accessories Processing ,stable processing quality, batch production, easy to control product quality. When machining parts change, only change the nc program can save the production preparation time, the machine tool itself has a higher precision and stiffness, can choose a better processing and higher productivity (generally for ordinary machine tool 3~5 times); The degree of automation of machine tools can reduce labor intensity, the professional quality of operators is low, the technical requirements for maintenance personnel is higher.

The above content is the introduction of CNC precision machining those things, CNC precision parts processing is the first premise of the accuracy of the processing benchmark. The datum on A mechanical drawing is represented by capital letters A, B, C, D, etc., all within A specific reference symbol circle. When the reference symbol is aligned with the extension line or the dimensional limit of the face, the reference symbol is based on the face. When the base symbol is aligned with a dimension line, it is a solid line based on size.