There are two main types of machining: manual machining and CNC machining. Manual machining refers to the method of machining various materials by manual operation of mechanical equipment such as milling machines, lathes, drill presses and sawing machines by mechanical workers. Manual machining is suitable for small batch, simple parts production. CNC machining (CNC) refers to the machining of CNC workers using CNC equipment. These CNC equipment include machining centers, turning and milling centers, wire EDM equipment, and thread cutting machines. Most machining shops use CNC machining technology. By programming, the position coordinates (X, Y, Z) of the workpiece in the Cartesian coordinate system are converted into a programming language. The CNC controller of the CNC machine tool controls the axis of the CNC machine tool by recognizing and interpreting the programming language, and automatically removes the material as required. , thereby obtaining a finished workpiece. CNC Product Customization processes workpieces in a continuous manner, suitable for high-volume, complex-shaped parts.

CNC Machining Aluminum Parts features

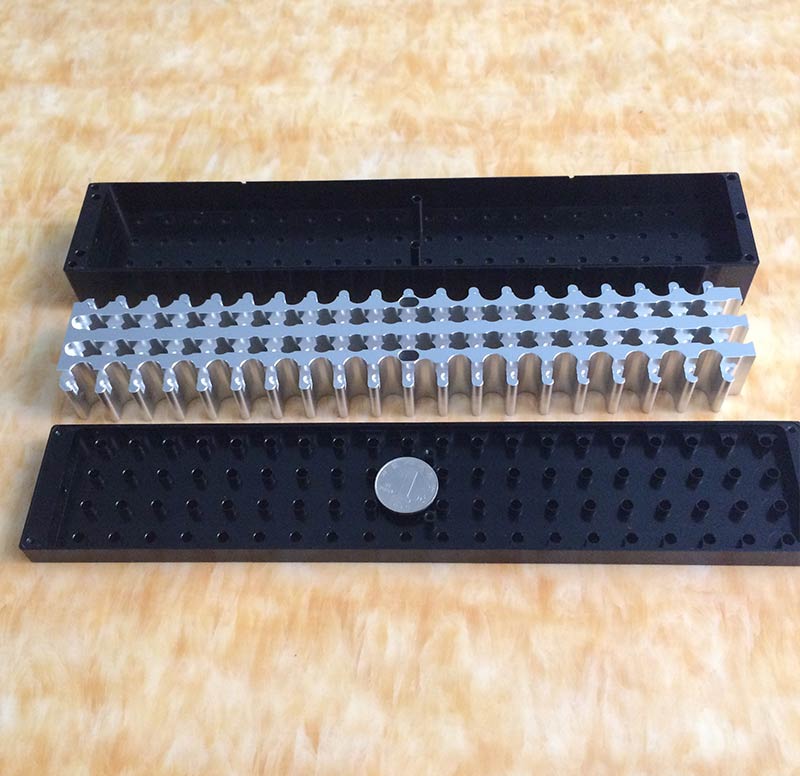

The CNC machining center is a CNC machine tool with a tool magazine that can automatically change tools and perform various machining operations on a workpiece within a certain range. After the workpiece is clamped once, the CNC system can control the machine tool to automatically select and replace the tool according to different processes; automatically change the spindle speed of the machine tool, the feed amount and the movement path of the tool relative to the workpiece and other auxiliary functions, continuously to the workpiece The machined surface is automatically machined in multiple steps such as drilling, boring, reaming, boring, tapping, and milling.